Progressive Die Stamping: A Game-Changer in Metal Fabrication

In modern manufacturing, progressive die stamping has transformed how industries approach metal forming. This advanced method streamlines production, enhances precision, and reduces costs, making it a preferred choice for high-volume metal fabrication. By integrating multiple operations into a single process, progressive die stamping eliminates the need for separate tooling, reduces handling time, and improves overall workflow efficiency. This innovation not only speeds up production but also ensures consistently high-quality results, helping manufacturers meet demanding industry standards with ease.

Understanding Progressive Die Metal Stamping

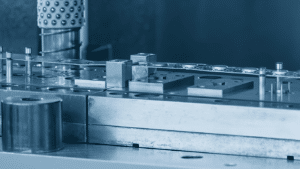

Progressive die metal stamping is a process that involves multiple stations within a single die. Each station performs a unique task—punching, bending, coining, or cutting—allowing for efficient production of complex metal parts. As a metal strip moves through the die, each station shapes the part incrementally, ensuring consistency and precision.

Solving Industry Challenges with Progressive Die Stamping

Manufacturers face challenges such as efficiency, accuracy, and cost control. Progressive die stamping addresses these pain points by providing a streamlined, automated process that enhances productivity and reduces human error.

Increased Efficiency and Precision

Traditional stamping methods require multiple tools and steps, leading to delays and potential inconsistencies. With progressive die metal stamping, every action is performed in a continuous sequence, reducing handling time and improving repeatability. This approach guarantees precision even for intricate designs.

Cost-Effectiveness and Waste Reduction

Cost efficiency is another major advantage of progressive die stamping. Since multiple operations occur within a single die, manufacturers cut labor costs and minimize the need for additional machinery. Additionally, progressive die metal stamping optimizes material usage, reducing scrap and promoting sustainable production.

Key Differentiators in Choosing a Progressive Die Stamping Partner

When selecting a progressive die stamping provider, businesses must consider several critical factors.

Expertise in Complex Die Designs

A reputable progressive die metal stamping partner must have expertise in designing and engineering complex dies. This expertise ensures precision in forming intricate components while maintaining durability and consistency.

Advanced Technology and Equipment

High-quality progressive die stamping relies on cutting-edge technology. Companies equipped with state-of-the-art machinery deliver superior results, ensuring high accuracy and efficiency in mass production.

Commitment to Quality Control

Strict quality control is essential in progressive die metal stamping. A reliable partner follows stringent inspection protocols at every stage to ensure all parts meet industry standards, eliminating defects and reducing waste.

The Advantage of In-House Tooling Capabilities

A progressive die stamping provider with in-house tooling capabilities offers substantial benefits.

Streamlined Production for Higher Quality

With in-house tooling, manufacturers oversee the entire process—from die design to final production—ensuring better coordination, faster turnaround, and superior quality control.

Efficiency in High-Volume Production

One of the standout features of progressive die metal stamping is its ability to produce large quantities of metal parts quickly while maintaining precision. The progressive die’s design allows continuous movement, reducing downtime and improving output consistency.

Cost and Time-to-Market Benefits

In-house tooling also contributes to cost savings and faster time-to-market. Eliminating third-party vendors reduces overhead, shortens lead times, and ensures rapid product deployment, making progressive die stamping ideal for competitive industries.

The Strategic Value of Progressive Die Stamping

In today’s manufacturing landscape, progressive die stamping and progressive die metal stamping stand out for their efficiency, precision, and cost benefits. Choosing the right stamping partner—one with expertise, advanced technology, and stringent quality control—ensures optimal production outcomes.

Selecting a provider with in-house tooling amplifies these advantages, enhancing efficiency, reducing costs, and accelerating time-to-market. This integration makes progressive die metal stamping not just a solution but a strategic asset for businesses aiming to stay ahead in the evolving manufacturing industry.

Ready to explore the benefits of progressive die stamping? Learn more about Frontier Metal Stamping on our website.